Rigid Plastics Recycling System

HDPE Bottle Container Washing Line

Background

Boretech offers advanced washing solutions for High-Density Polyethylene (HDPE) products, designed to maximize recycling value and deliver clean, reusable material for downstream applications. These systems are engineered for efficiency, high capacity, and superior end-product quality.

Rigid HDPE Washing Line

The rigid hdpe washing line is suitable for recycling daily use rigid plastic (especially those with high recycling value such as HDPE mike container / small HDPE blue container as well as 2.5L motor oil containers.) This washing line can greatly increase the value of the final product and belongs to our high-end equipment series.

HDPE Oil Container Washing Line

Specifically designed for processing post-consumer motor oil containers, this line performs a series of screening, crushing, and washing operations to transform used containers (2.5L or smaller) into clean, reusable resources. These containers are most commonly made of polyethylene (including HDPE) and the processed material can be used in roto-molding, extrusion, pallets, plastic traffic cones, and more.

Rigid Plastics Washing Line

A versatile washing line for rigid waste plastics used in daily life, capable of handling HDPE along with other materials (PE, PP, LDPE, PO, PS, EPS, ABS, PA, PC, PVC). Through classification, crushing, and washing, this system produces clean, reusable materials suitable for a hard plastics closed-loop. Common HDPE applications include hollow consumer goods, plastic toys, small household products, and blue plastic vats.

Key Features of the Boretech HDPE Washing Line

- Boretech HDPE Washing Line is designed to process a wide range of HDPE products such as milk containers, blue drums, and motor oil bottles. With a process design proven over the years and a hot chemical washing module, the line achieves superior and consistent quality for the final HDPE flakes.

- The entire HDPE washing line can be equipped with a DCS system and PLC control to minimize manpower requirements and ensure stable operation.

- The washing line is equipped with a chemical water circulation system and an online rinse water circulation system to reduce water consumption and carbon footprint.

- The line features a one-button start/stop control for easier operation and simplified maintenance.

HDPE Washing Line Operation Video

HDPE Washing Line Capacity

Rigid HDPE Washing Line : 1500 kg/h~3000 kg/h

HDPE Oil Container Washing Line : 500 kg/h-1000 kg/h

Rigid Plastics Washing Line : 1500 kg/h~3000 kg/h

HDPE Washing Line Process

- Feeding

- Shredding

- Metal Removal

- Flotation Separation

- Crushing

- Drying

- Friction Washing

- Rinsing

- Drying

- Zig-zag Separation

- Pneumatic Conveying

- Optical Sorting (optional)

- Packing

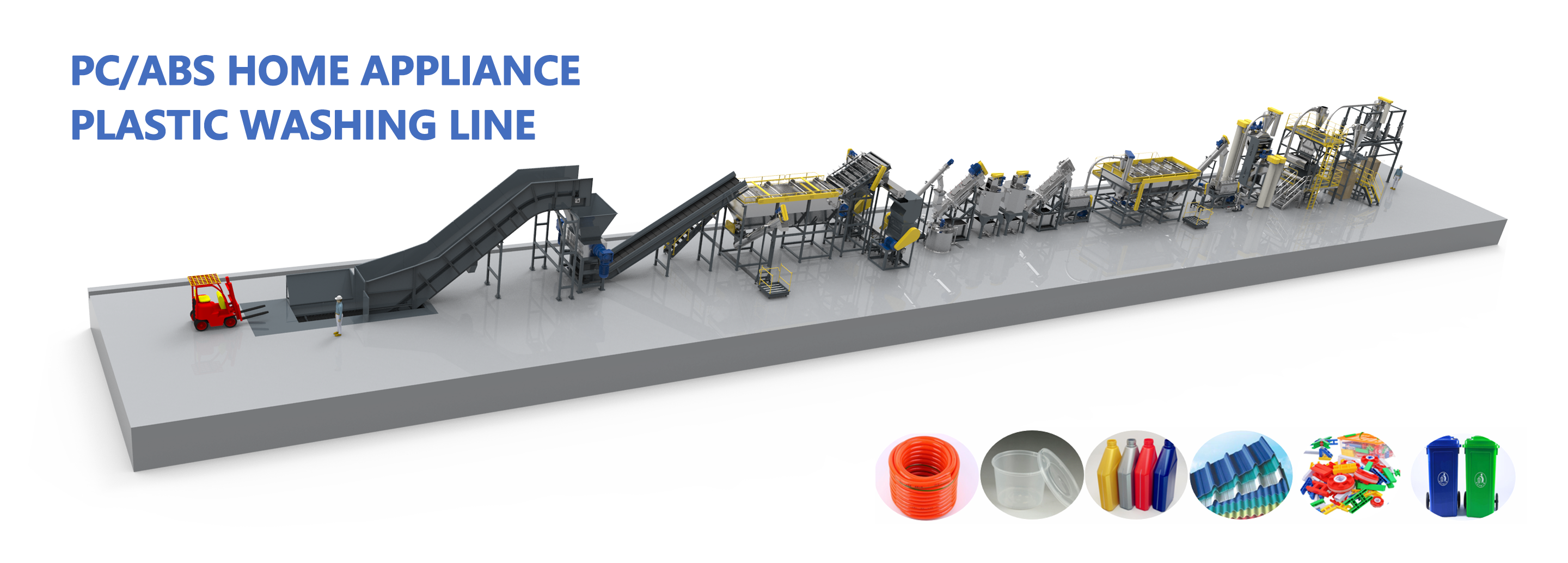

3D Layout

recycling cleaning system0129 _pic.png)

_pic.png)

recycling line_pic.png)

Applications of HDPE Bottle Container Washing Line

HDPE Flakes

HDPE Pellets

HDPE Pipe

HDPE Bottles

LDPE Pellets

Blown Film Extrusion

Powder Coating

Extrusion Coating

Injection Molding

_pic.jpg)

_pic.jpg)