Leader - Top Technology of PET Bottle Washing Line

Food Grade PET Bottle Washing Line

Background

Bottle-to-Bottle grade PET bottle washing line makes the sustainable development of PET bottle resource recovery come true.

The global PET resources are being exhausted, but its demand is increasing year by year. The overexploitation of petroleum has caused irreparable damage to the natural and earth, human beings are suffering from nature.

Sustainable development of PET resources recovery has been a major issue in the PET recycling industry. Full utilization of PET resources and 100% recovery of PET resources to achieve sustainable development is the ultimate goal of recycling. At present, the mainstream process to realize the recycling of PET bottles (containers) is physical recycling. Post-consumer PET bottles are collected from urban, it is recycled into rPET flakes by washing and crushing which rPET flakes can be used to manufacture food-grade chips. This kind of rPET flakes meets the standard of FDA which is available to contact food and beverage directly.

Bottle-to-Bottle grade PET bottle recycling makes the sustainable development of PET bottle resource recovery come true.

Product Feature

The food-grade PET bottle washing line is mainly used for PET bottle-to-bottle project (FDA Approval), which recycles post-consumer PET bottles into rPET flakes. The regenerative PET flakes conform to the quality index requirements of downstream food packaging and are used for bottle blowing and packaging which can directly contact food after pelletizing and SSP processes in the late stage. The food-grade PET bottle recycling process is more complicated than normal PET recycling, and the requirement for equipment and the quality of the final rPET flakes are more strict. At the same time, the owner is required for higher factory management and advanced production knowhow. BoReTech food-grade washing line has higher automation to avoid human errors. Ultra-cleaning of PET bottles and flakes, efficient blending, and an online inspection system to ensure that the output of recycled PET flakes meets the standard of food-grade PET bottle-to-bottle process (FDA Approval). Meanwhile, the BoReTech food-grade PET bottle recycling system process is optimized according to the post-consumer PET bottle condition from different countries with the economic cost, less space occupation, and the most advanced process technology to meet the variety of downstream production applications. With more than 20 years of experience in PET bottle recycling production, BoReTech provides online production and process guidance to customers. BoReTech PET bottle recycling system adopts a SCADA system combined with a PLC controller, which can display parameter data of each unit and single PET bottle recycling equipment intuitively and effectively, and at the same time the system can record all production data, and it has combined the remote communication technology to allow communication between customers and BoReTech engineers by the internet and give them real-time guidance. BoReTech can assist customers with practical production management, data analysis, and equipment daily maintenance. In addition, the entire PET bottle system is equipped with an optical bottle sorter and flake sorter, which greatly reduces the investment of labor and improves production efficiency, thereby truly achieves a highly automated and clean recycling system. PET bottle bales are sorted, crushed, and washed by the food-grade PET bottle washing line, and finally generated high-quality rPET flakes. A number of well-known customers of BoReTech have obtained FDA approval of rPET flakes and supply these PET flakes to downstream brand beverage manufacturers. BoReTech analyses post-consumer PET bottles from various countries and is developing a short (compact)-process PET bottle recycling system for these post-consumer PET bottles in specific countries and regions. The developing system integrates multiple functions of a single machine and greatly reduces space occupation and investment. rPET flakes recycled by compact line can also meet the requirement of the food-grade application and micro-denier filament grade applications. It will be launched at the end of 2020. BoReTech provides equipment and engineering service of PET bottle-to-bottle plant, please refer to https://www.bo-re-tech.com/en/solution/PET-Bottle-to-Bottle-Recycling-Plant.html

Highlights

1. Solutions for diversification of input PET bottle bales.

2. Automatic de-baling technology, reduces labor, a strong bale breaking ability for high-density PET bottle bales.

3. Patent technology for PVC label removal.

4. Patented Pre-washing and hot washing process to ensure the cleanliness of rPET flakes.

5. Integrated technology and capability for automatic sorting machine and PET bottle recycling line.

6. The hot washing process reduces impurities content to achieve food-grade index.

7. Stable and reliable quality of rPET flakes, online inspection ro ensure the stability of rPET flakes.

8. Completed online water recycling treatment system for pre-washing, hot-washing and rinsing.

9. Low operation breakdown, production management guidance service for customer.

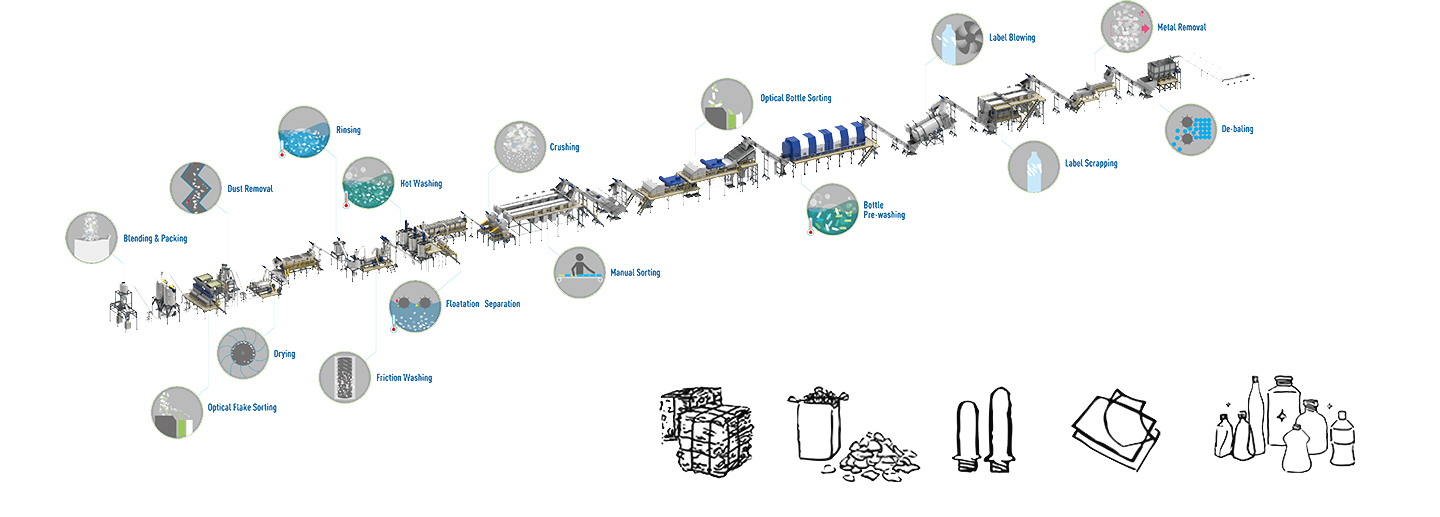

BORETECH PET BOTTLE RECYCLING SYSTEM AND PROCESS FOR FOOD GRADE FLAKES

Input Capacity

1500-10000 kg/h

Model Options

3D Layout

Food Grade PET Bottle Recycling Process

De-baling➜Metal Removal➜Label Removal➜Metal Removal➜Bottle Pre-washing➜Optical Bottle Sorting➜Manual Sorting➜Crushing➜Dust Removal➜FlotationHot washing➜Friction Washing➜Rinsing➜Flushing Washing➜Drying➜Dust Removal➜Optical Flakes Sorting➜Blending➜Online Inspection➜Packing

Ps. A standard sampling of food-grade PET bottle recycling process, equipment configuration and the process will be optimized according to raw materials

Downstream Applications of Food Grade rPET Flakes

rPET flakes

rPET chips

Preform

rPET Container & Tray

Beverage bottles